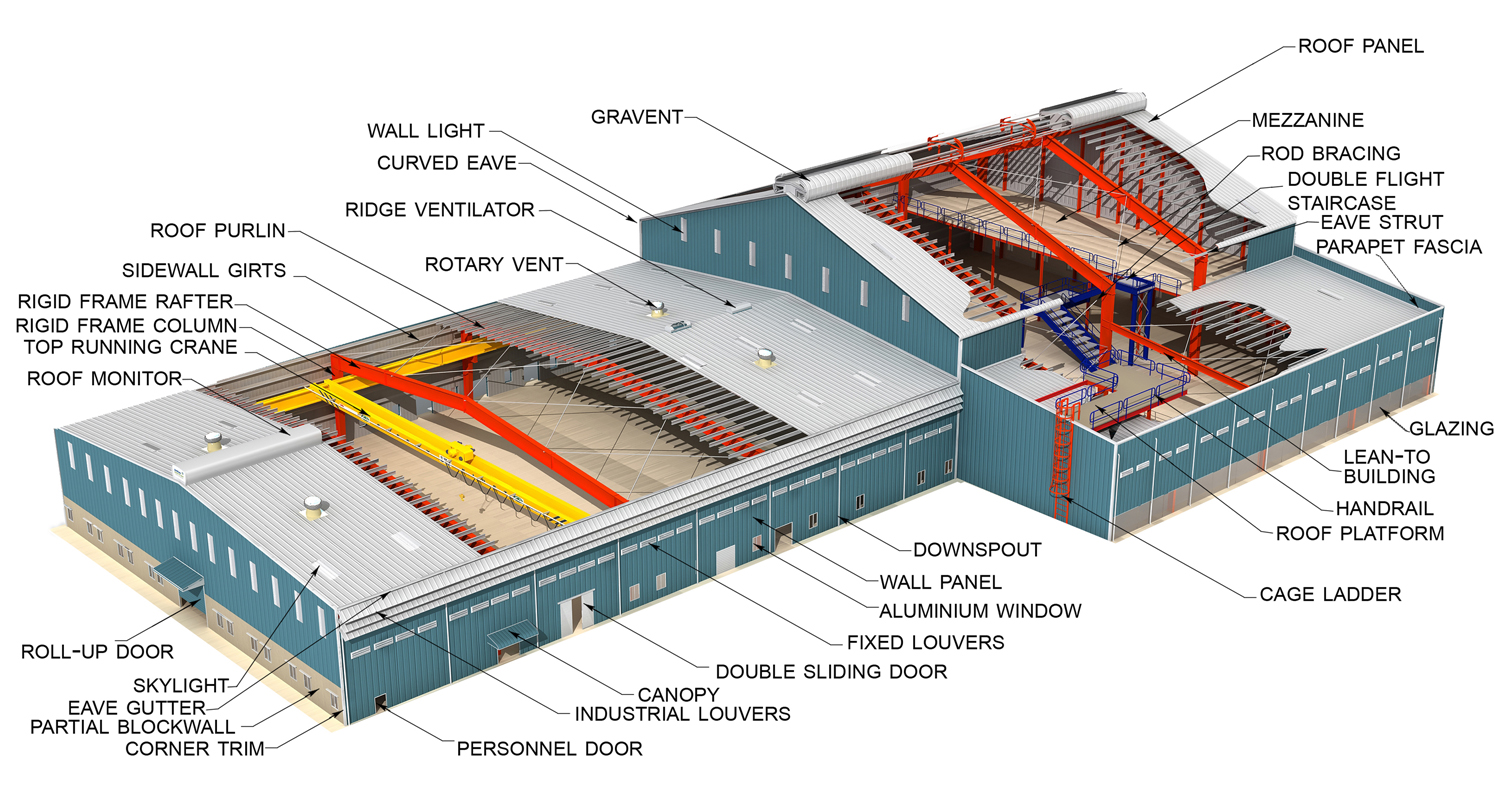

COST EFFECTIVE AND DURABLE ALTERNATIVES TO TRADITIONAL BUILDINGS

We are a leading manufacturer of pre-engineered buildings (PEB). We offer turnkey solutions for multi-storey PEB, and we’re gaining a strong client network because of our countless benefits.

The cost effective nature and long lasting property of these structures make us one of the most sought-after construction choices. We can customize these structures to meet a wide range of structural and aesthetic design requirements. These pre-engineered building structures are supported by light gauge steel framing (LGSF) and enveloped in insulating composite panels. This makes these structures a great alternative to conventional masonry and concrete construction for literally endless applications.

Pre-engineered buildings are best suited for industrial structures like warehouses, factory buildings sheds, commercial buildings, airport terminal buildings, and a wide range of other building solutions.

BENEFITS OF PRE ENGINEERED BUILDINGS

They are cost-effective:

A basic cost-saving example is the use of a standard seam roof. When compared to a membrane-style roof, savings can prove significant. Although, it is important to note cost savings of PEB will be unique and dependent on the scope for each project. The use of sheeting can help further drive down cost but roofing is where the main cost advantages live with PEB. Work with your architectural and construction firm to understand your local market and the conditions which may impact choice of a roofing system for your PEB.

They offer time savings:

With materials and designs pre-chosen, erection of a facility can be much quicker and more efficient than a conventional building. In addition, finding a building firm which can self-perform erection can further shave off time.

They are versatile and offer architectural options:

An architect or customer can choose from several wall panels adding to the versatility in design. PEB design options for roof systems and walls depend on the owner’s needs. A standard seam roof is the typical rooftop used in PEB, but an architectural firm that specializes in PEB can work with you to customize and match a vision which meets your needs. Pre-engineered doesn’t have to mean cookie-cutter or dull.

They are quality and durable structures:

Because the PEB are pre-fabricated in a controlled setting, durability and quality can be achieved. Pre-engineered roofs last longer than other roof systems if installed properly. The process and system of erecting PEB roofs involves clips attached to the main steel, which then connect to the roof. A machine seals the roof to the clips which allows it to expand and contract. This creates a durable roof which can outlast the harshest wind conditions. If you think back to fly-over videos from hurricane-devastated areas shown on the news in the past, the roofs which remain standing are typically metal roofs erected through this process.

They are low-maintenance:

PEB maintain their appearance throughout the life of the building due to the quality built into the process and the raw materials used. Steel is rust and corrosion resistant. This creates a solid structure and foundation which is virtually maintenance-free for a longer period than conventional buildings.

They are sustainable:

Recycled content, recyclability, and minimal environmental impact due to their life-cycle costs make PEB an ideal choice when looking to incorporate sustainability and green construction into your next project.

-19.jpg)

-12.jpg)

-18.jpg)

.png)

.jpg)

.jpg)

.jpg)